$237.00

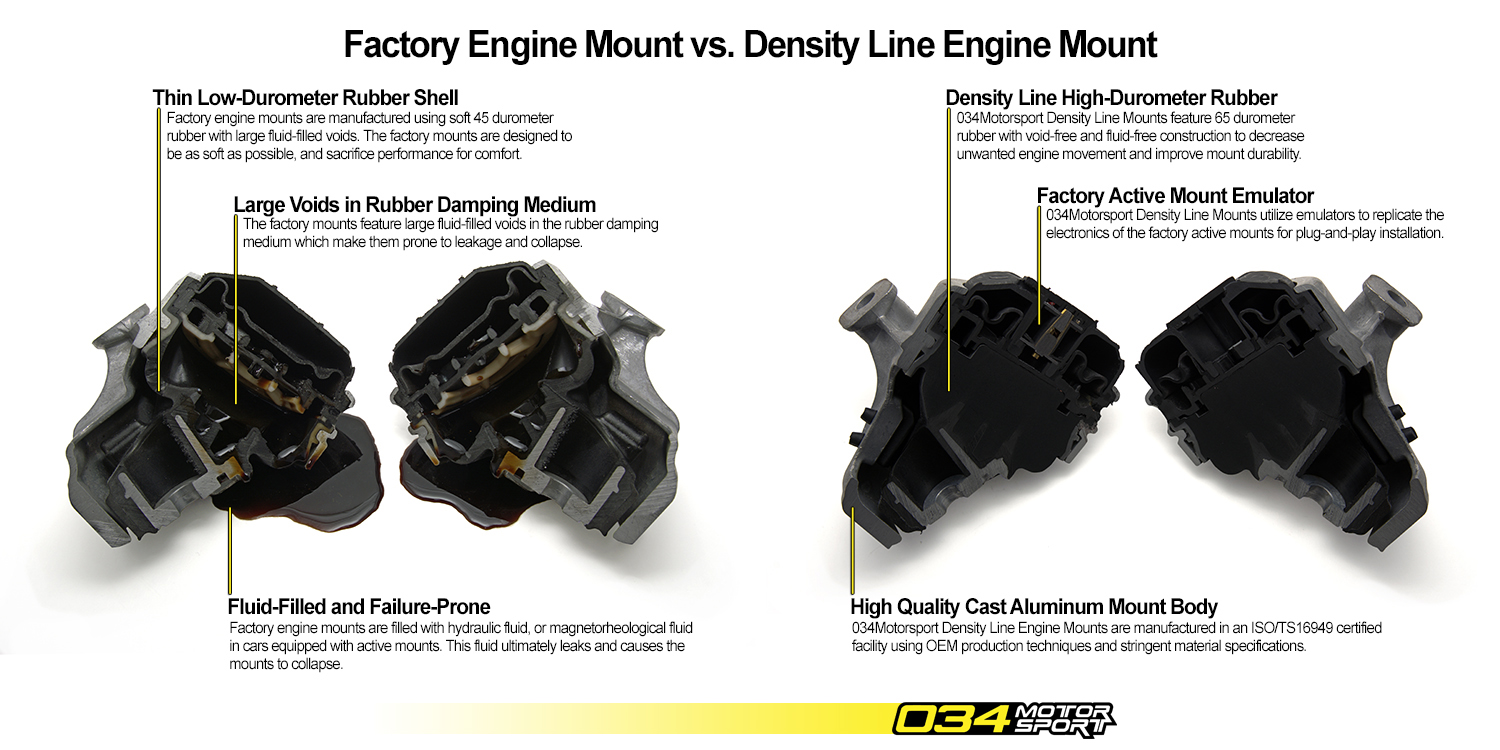

034Motorsport’s Density Line Mounts are the new standard in comfort and performance. Our mounts are redesigned with performance in mind, and manufactured from high-durometer rubber for increased performance and durability, without sacrificing comfort. Density Line Mounts are void-free and fluid-free, eliminating the slop and the possibility of leakage and collapse associated with the factory mounts. The mount bodies are made from high quality cast aluminum using OEM production techniques and employ emulators to replicate the electronics of the factory engine mounts for plug-and-play installation. This ensures MIL-free operation for cars equipped with active engine mounts.

Density Line Mounts are manufactured from high-durometer rubber instead of polyurethane for a number of reasons. While vulcanized rubber mounts are more expensive to prototype due to the complexity of manufacturing and high initial tooling costs, rubber is inherently better than polyurethane as a damping medium for mounts and bushings. Rubber is able to deal with stress under both tension and compression, while polyurethane mounts rely on the damping medium to be effective only under compression. Rubber is also excellent in shear, where polyurethane is ineffective, making it ideal for applications that apply a shear force to the bushing during articulation. Rubber does not pack and wear like polyurethane does, which ultimately results in a long-lasting part with consistent performance and comfort.

Features:

Note: This mount has two different applications that is based on engine size (Track for 4-cyl and Street for 6-cyl). Please see the Fitment Guide tab below for application information.

We recommend installing our popular Transmission Mount Insert along with these motor mounts to minimize unwanted drivetrain movement, with a slight increase of NVH.

Sold Individually (One Vehicle Requires 2 Mounts)

Installation Instructions:

Warranty:

High-Durometer Rubber vs. Polyurethane:

Density Line Mounts are manufactured from high-durometer rubber instead of polyurethane for a number of reasons. While vulcanized rubber mounts are more expensive to prototype due to increased complexity of manufacturing and high initial tooling costs, rubber is inherently better than polyurethane as a damping medium for mounts and bushings.

Rubber is able to deal with stress under both tension and compression, while polyurethane mounts rely on the damping medium to be effective only under compression. Rubber is also excellent in shear, where polyurethane is ineffective, making it ideal for applications that apply a shear force to the bushing during articulation.

Rubber does not pack and wear like polyurethane does, which ultimately results in a long-lasting part with consistent performance and comfort.

Reviews

There are no reviews yet.